Case Study

Reducing Biosolids Production at Point Source

A UK Water Company carried out a series of full-scale demonstrations at various municipal wastewater treatment works some of which received industrial discharges. This WWTW, with a design PE of 16,267, was used as a control as there were no industrial discharges and asset was operating within discharge consent at beginning of demonstration. The on-site, full-scale demonstration took place over a period of 8 months with the support of the Water Company in terms of operational, oversight and validation of results.

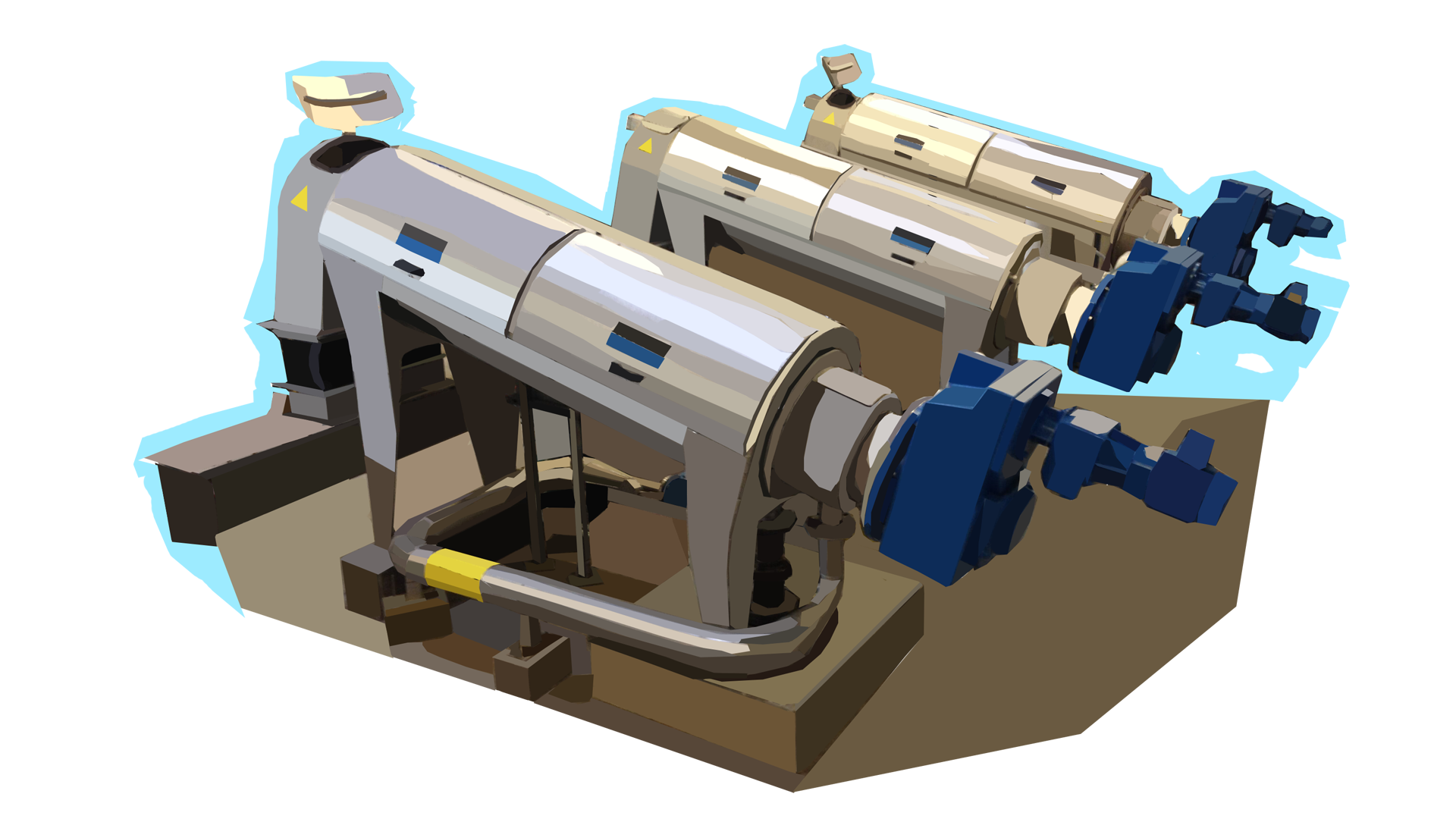

The WWTW consists of preliminary treatment followed by two trains each with anoxic zones, aeration and a clarifier as shown in Figure 1, while Table 1 describes the operating conditions for each period.

OBJECTIVES:

To determine whether Biofermentation® would:

– Improve treatment capacity and/or effluent quality

– Reduce the mass of secondary solids produced

– Reduce OPEX: polymer usage, electricity and hauling

RESULTS

To evaluate the impact of Biofermentation® the data was normalised based per kg of BOD removed for sludge production , polymer usage and electricity to account for increases in loading and improved effluent quality in the test period. The results of this work were:

– 44% less solids produced using normalised data without optimisation of the operation

– Settleability of the biomass improved by 12%

– Effluent quality was improved significantly: BOD 57%, Suspended Solids 46% and ammonia 10%

– OPEX was reduced significantly: Polymer usage 40%, electrical 27% and exports 22%

BENEFITS TO THE UTILITY

Ability to sweat the asset by obtaining more throughput: BOD 125% and Suspended Solids

143%

Improved effluent quality despite overloaded situation and limitations of oxygen

transfer

Reduced solids production. With optimization solids production could be reduced further

confirming results found in USA where typically 60%+ reduction is observed

The Biofermentation® Program demonstrated the ability to be “revenue positive” for OPEX with no

CAPEX required

The technology provides the Utility with the ability to meet a significant portion of the UK

2030 Net Zero Carbon targets