Elimination of Alum Usage & Reduction of In-Situ Biosolids Handling

11 Megalitre/Day plant with primary clarifiers and percolating filters sending reuse water to a local paper mill. Solids handling was via anaerobic digestion and thereafter belt presses for thickening followed by hauling to landfill for compositing.

The plant was experiencing operational challenges for effluent BOD compliance and maintaining low turbidity for reuse of water requiring continuous use of alum with associated high costs of operation.

This project has been continuous since 2008.

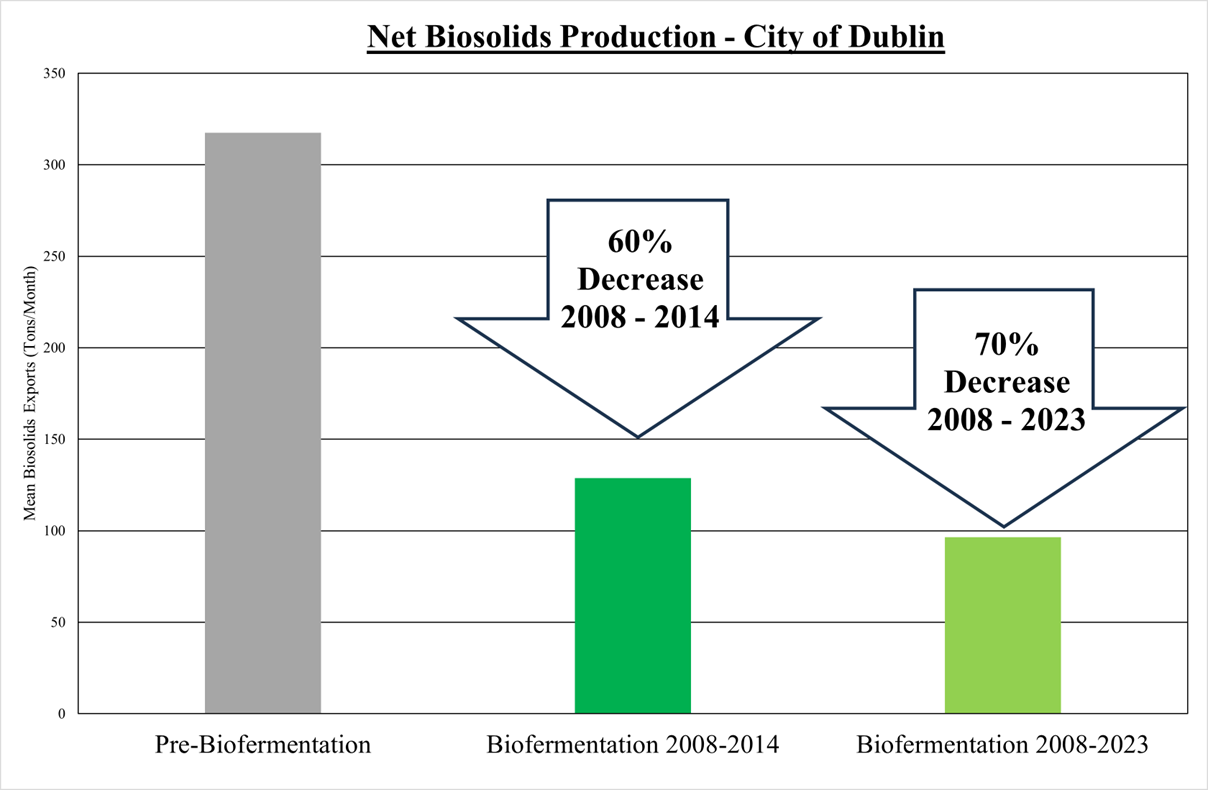

Alum usage was eliminated within 3 weeks and has never turned back on while biosolids hauled were reduced by 60% on average (excluding alum) by 2014. This increased to an average of 70% by 2023 excluding any alum sludge.

A net savings of 40+% on operating costs was achieved by the elimination of alum usage representing around $80,000+ pa, plus 70% reduced costs of biosolids handling. In 2013 the Utility started treating landfill leachate in addition to normal wastewater loads creating an additional revenue stream. In 2014, the Utility started treating FOG in the collection system using ABS’s satellite distribution systems. In 2024, ABS has been asked to investigate pretreatment of Landfill leachate and further digestion of sludge in the anaerobic digestors.